2D-Code Inspection

Two dimensional codes are increasingly used on product packaging. The combination of high information density and fault tolerant encoding make them the preferred method for machine readable object marking. The proliferation of digital and ink-jet technologies has made printing of variable 2D codes practical and has spawned numerous applications for product tracking, identification and counterfeit protection.

The readability and the correctness of the 2D code on a package are of great importance to the label printer. Code mistakes should be detected as early as possible in the production process. Automatic inspection technology provides valuable assistance in achieving these quality goals. Many print problems in static 2D codes can be detected by Alis and ODRI inspection systems with standard inspection algorithms. The 2D code is inspected as a printed pattern.

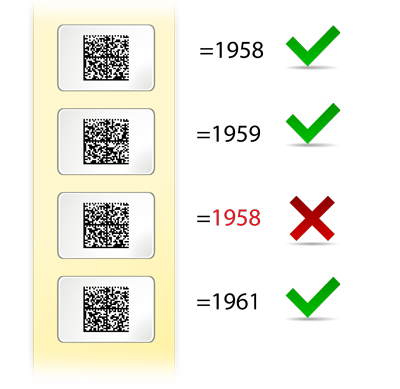

To further extend the functionality of the Alis and ODRI inspection systems for 2D codes, we have developed the 2D Barcode module. It adds decoding, quality evaluation and data logging capabilities to the systems. Simultaneously with the standard print quality inspection, 2D codes in the image are scanned, decoded and evaluated. The decoded clear text values are checked for correctness, recorded and print quality is evaluated. Should any of these checks fail, the label is flagged as defective. The system checks all 2D codes passing under the camera.

The 2D Barcode module can decode, verify and store sequential codes. The variable information is provided by a database server. The decoded values are stored in data files and can be exported for further processing, for example in a counterfeiting protection scheme.

The 2D Barcode inspection module is fully integrated in Nikka’s electronic job ticket interface. The job description file can provide the 2D code values in clear text, quality criteria, rules for sequences and external links to database files. In this way the inspection and verification of the 2D code is fully automated, greatly reducing the risks from manual configuration.

List of supported symbologies:

- Datamatrix

- ECC200

- QR Code

- PDF 417

Products supporting 2D Barcode decoding module (* optional, minimal bar code size dependent on camera resolution).

English

English

Deutsch

Deutsch